(All day)

fax:0769-22711927

e-mail:[email protected]

Address: xiagongkan industrial zone, jianshazhou community, wanjiang district, dongguan city (no.1 factory)

Address: intersection of weiyi road and jinger road, economic development zone, quanjiao county, chuzhou city, anhui province (no.2 factory)

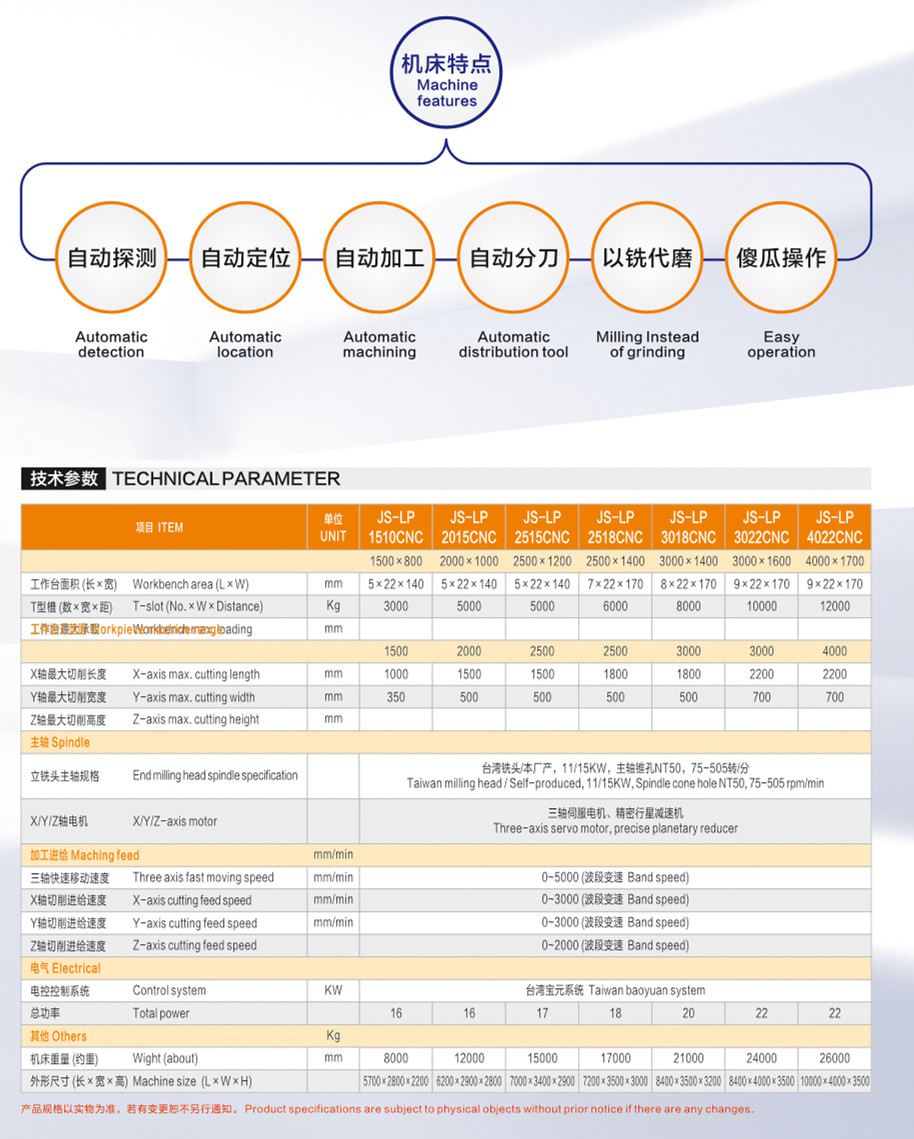

CNC Surface Finishing Machine

I. description of machine tool performance

This machine is a fixed-beam CNC planar fine milling machine, equipped with feed servo drive speed system and spindle torque shift speed regulation, multi-axis control (table longitudinal movement, vertical milling head lateral movement, vertical milling head lifting movement). Automatic detection, automatic processing, automatic positioning, CNC intelligent, milling instead of grinding, processing steel plate, both sides of the plane rough and fine processing as one, heavy cutting die blank, high precision, boring and milling machining application processing equipment.

Main structure and performance characteristics

1. Main components of the machine tool

The machine is mainly composed of base, work table, column, sliding seat, beam, electrical, lubricating oil, screw, motor, electric control, plate gold shield and other parts.

2. Structural layout and features

The machine adopts fixed beam gantry structure, the bed is fixed. The table moves X forward and backward over the bed; The sliding pillow and the sliding seat of the end milling head move Y to the left and right on the beam; The sliding pillow of the end milling head moves Z up and down on the sliding seat; , the bed forms a solid structure of fixed beam and column of the gantry, which ensures the rigidity of the machine tool as a whole, and at the same time ADAPTS to the design principle of stable combination of heavy cutting and light cutting. The machine layout is reasonable and beautiful.

3. Material quality and processing technology of large parts

The main large pieces such as the base, bed 5 large pieces are used box or approximate box structure, large size structure, and layout is enough to strengthen the steel plate, such as columns in the middle of the layout of a pair of integral steel plate, the bed cavity is used intensive "honeycomb" well type steel plate layout; The main large parts are cast by high strength ht250-300 m Hannah cast iron and resin sand process, after whole annealing treatment, natural aging treatment and two high frequency vibration aging treatment, with high rigidity, high stability, to achieve the effect of prolonged deformation. All parts of the processing process in jiasheng company, the use of imported high-precision working machine and the site guidance by senior engineers to ensure the accuracy, every single piece by grinding, single precision control within 0.01mm per meter, the whole machine does not use any gasket to adjust the accuracy, durability is better.

4. Main drive: vertical spindle

(1) end milling head adopts the boring and milling head imported from Taiwan (15HP/11KW). Adopt multi-gear transmission structure, short transmission chain, the best spindle accuracy, ensure the spindle running smoothly, low noise, long service life and other characteristics. The structure is especially suitable for medium and low speed machining functions. Spindle infinitely variable speed, low speed and large torque, rough and finishing.

(2) spindle with precision roller and angular contact spindle imported bearing, supporting span, spindle rigidity, smooth operation, precision and good maintenance. As an independent component, the spindle assembly has good manufacturability, convenient and reliable adjustment of bearing preload, and convenient maintenance.

5. Four-way guide rail

X direction adopts super heavy linear double V type guide rail, the center of the guide rail is far from the span, plus Japan imported 2mm thick wear-resistant tape, high motion sensitivity and operation accuracy, strong bearing capacity.

The Y direction USES the ultra wide rectangular guide rail, the guide rail combination structure form rigidity is good, the friction coefficient is small, the motion sensitivity is high, the performance is superior, the bearing capacity is big, can withstand the strong heavy cutting, and the precision stability of the machine tool is very good, the service life is long.

6. Triaxial feeding mechanism

(1) X, Y, Z direction feed mechanism adopts original ball screw drive from Taiwan, servo motor + planetary reducer drive, greatly improving the torque driving force. The servomotor drive of the screw rod with left and right stroke of the beam has good feed driving characteristics, simple structure and convenient maintenance.

(2) the z-axis adopts C3 level ball screw + precision planetary reducer, and the slider adopts ultra-wide type lengthening up and down stroke design to ensure the high accuracy of the z-axis repeat positioning.

7. Milling head accessories

(1) end milling head spindle cone is NT50, large torque full gear box, maximum output speed 1000 R.P.M.

8. Lubricating system

Spindle bearings are lubricated with high quality grease. Main drive double speed transmission adopts external lubricating pump for automatic circulating thin oil cooling and lubrication. Guide rail, ball screw and other moving parts have perfect centralized lubrication system, which can realize timing and quantitative automatic lubrication.

9. Safety protection

(1) the X - and y-direction guide rail is protected by stainless iron telescopic protective cover, and the Z - direction guide rail is also equipped with protective devices to ensure the reliability and service life of the guide rail and the screw rod.

(2) main motor and feed motor are equipped with overload and overheating electrical protection functions. Each direction feed mechanism is equipped with limit and limit block control device, in line with the international CE safety certification standards, safe and reliable operation of the machine tool.

(3) machine tool working light.

(4) all moving pipelines are protected by metal or non-metal chain devices.

(5) end milling head plus multi-air pressure blowing energy

Performance characteristics of main electrical control parts

1, X, Y, Z, three-way feed adopts ac speed regulating system and servo motor to control and drive respectively, with advanced performance, reliable work and convenient operation.

2. X, Y, Z and tridirectional feed control have the characteristics of rapid triaxial continuous movement and convenient operation, etc.

Address: xiagongkan industrial zone, jianshazhou community, wanjiang district, dongguan city (no.1 factory)

Address: xiagongkan industrial zone, jianshazhou community, wanjiang district, dongguan city (no.1 factory)  Phone-Number:0769-22711926

Phone-Number:0769-22711926  E-Mail:

E-Mail:  About Us

About Us trait

trait News

News